Scorpion HK-4025-630KV (6mm Shaft) Brushless Outrunner Motor for 550/600-class EP helicopters

Specially Design for 12S Li-Po! Ideal Upgrade for Align T-Rex 550/600 and other 550/600-class EP helis! Higher Efficiency, Less Heat, More Power!

The Scorpion HK-4025 motors have been developed for the 550 to 600 class electric helicopters and the HK-4025-550KV motor is suitable for the glow to electric conversation of 50 size helicopter. These motors are designed to provide all the power that you can use, while still maintaining excellent efficiency and cool running characteristics.

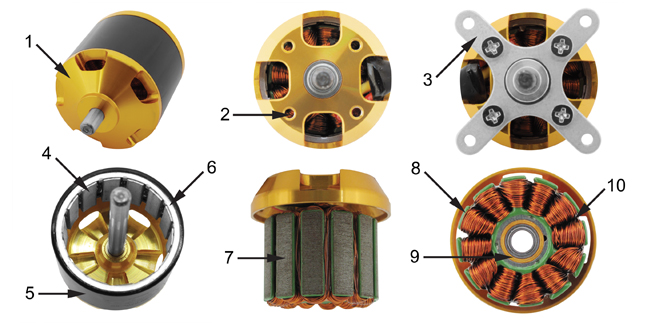

Scorpion HK Series Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold anodized to provide a beautiful, long-lasting finish. The stators are made with 0.2mm laminations to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts, and are wound with wire that is rated at 180 degrees C (356 F). The magnets used in Scorpion Motors are rated for operation at 200 degrees C (392 F), making a motor that is virtually impossible to burn up in normal use.

This Scorpion HK-4025-630KV motors come with 4mm male Bullet style connectors already attached, and include a hardware package that contains 3 matching female Bullet connectors for your speed controller with matching heat shrink tubing. For maximum strength, this Scorpion HK-4025-630KV motors feature an 8mm motor shaft that is ground down to a 6mm diameter at the output end to fit standard size pinion gears. Since the HK series motors are primarily designed for Helicopter and Ducted Fan use, they do not include a prop adapter. If you intend on running a prop on this motor, you will need to purchase a prop adapter for a 5mm shaft.

Scorpion Motors are built to last, and are backed with a 2-Year warranty against defects in materials or workmanship. However, due to the high RPM of these motors, and the fact that we cannot control the installation and setup, the bearings are not covered by the 2-Year warranty, nor is any subsequent damage caused to the motor by a bearing failure. Bearings are a normal wear item, and as such, need to be maintained and changed periodically. For maximum life, make sure that a sufficient gap is left between the pinion and main gear during motor installation to avoid binding, and put a small drop of oil on each bearing every 5-6 flights. It is the responsibility of the pilot to ensure that the bearings are maintained properly.

For the best overall combination of quality, performance, and value, uses Scorpion Motors in your helicopter!

Specifications

|

Stator Diameter |

40 mm (1.56 in) |

|

Stator Thickness |

25 mm (0.98 in) |

|

No. of Stator Arms |

12 |

|

Magnet Poles |

8 |

|

Motor Wind |

12T Delta |

|

Motor Wire |

20 - Strand 0.25mm |

|

Motor Kv |

630KV RPM / Volt |

|

No-Load Current (IO) |

1.1 Amps @ 8.4v |

|

Motor Resistance (RM) |

0.024 Ohms |

|

Max Continuous Current |

65 Amps |

|

Max Continuous Power |

2700 Watts |

|

Weight |

326 Grams (11.50 oz) |

|

Outside Diameter |

48.9 mm (1.9 in) |

|

Shaft Diameter |

5.98 mm (0.235 in) |

|

Body Length |

51.5 mm (2.01 in) |

|

Overall Shaft Length |

83.7 mm (3.30 in) |

|

Max Lipo Cell |

12s |

|

Peak Current |

90 Amps (5 seconds) |

|

Peal Power |

3700 Watts (5 seconds) |

|

Motor Timing |

5deg |

|

Drive Frequency |

8kHz |

About Scorpion

Scorpion Model Products is pleased to announce the release of our new series of Brushless Outrunner Motors. These motors raise the bar in both quality and performance, and are establishing themselves as the new Gold Standard for model aircraft power! All of the Scorpion Brushless Motors are manufactured from the finest quality components using state of the art CNC machine tools. Every component of the motors are of the highest quality, from the materials used, to the box they ship in. They are designed to provide reliable power for your model aircraft at affordable prices, offering a total performance solution.

Scorpion Motors are designed from the ground up with the best quality components available to provide an excellent value for you, the R/C modeler. We utilize high quality aluminum alloys that are CNC machined and anodized for a fit and finish that is second to none. Unlike other motor manufactures that use off-the-shelf N50 NdFeB magnets with a maximum Curie temperature of 80 to 100 degrees C, our motor magnets are custom manufactured to be able to withstand temperatures of up to 200 degrees C (392 F) while still providing N50 magnet strength. The wire we use to wind the stators is rated to 180 degrees C (356 F), so it can take the heat and keep on performing. This all adds up to a motor that can provide you the power you need, without going up in a cloud of smoke if you push it a little too hard. With all these features, you would expect to pay top dollar for a motor of this caliber, but with our efficient manufacturing procedures and streamlined distribution chain, Scorpion motors retail for about 1/2 the price of other "Name Brand" Brushless Motors, making them one of the best overall values on the market today. We are so confident in the quality of our motors that we back them with a 2-Year Warranty against defects in materials and workmanship (covered by the Scorpion Repair Facility). You deserve the the best quality motor available at an affordable price, so the next time you need a brushless motor, do yourself a favor and give Scorpion Brushless motors a try, you will be glad you did!

The Top Ten Reasons Why You Should Try Scorpion Brushless Motors

-

Machined aluminum front housing with 5 angled cooling holes that pump air through the motor while it runs.

-

Rear threaded mounting holes with both 16 mm and 19mm hole spacings fit a variety of applications.

-

A machined aluminum cross style mount with hardware and a threaded prop mount is included with every motor, along with a wobbly adapter on select models.

-

Specially designed NdFeB magnets with a 200 C (392 F) temperature rating for trouble-free operation.

-

Durable black Electro-Coat finish on the flux ring to look good for years to come. We also laser engrave our logo and model number on each motor instead of using a sticker to help maintain the balance of the motor.

-

Rear locking ring maintains magnet spacing and also helps to strengthen the rear end of the flux ring assembly.

-

High quality stator plates are epoxy coated on the inner surface to prevent winding shorts. 0.20mm stator plates are used on the 22mm motors, with 0.35mm stator plates on larger sizes.

-

High Temperature 180 C (356 F) rated wire is used for winding the motors to minimize the risk of burning up the motor. The motors are also machine wound to ensure consistant winds.

-

High quality shielded and permanently lubricated ball bearings are used to support the motor shaft in all our motors.

-

High temperature adhesives are used to secure the stator windings and prevent them from shifting and getting pinched or shorting out .

Software Download for Scorpion Products:

http://www.scorpionsystem.com/downloads/

You can also calculate the performance data with the Scorpion Calculator:

Scorpion_Calc_v3.49.zip

|